A new dimension

A new technology that represents the biggest change in manufacturing since the computer or a limited fad with the potential to severely restrict the job market?

A new technology that represents the biggest change in manufacturing since the computer or a limited fad with the potential to severely restrict the job market?

For 3D printing

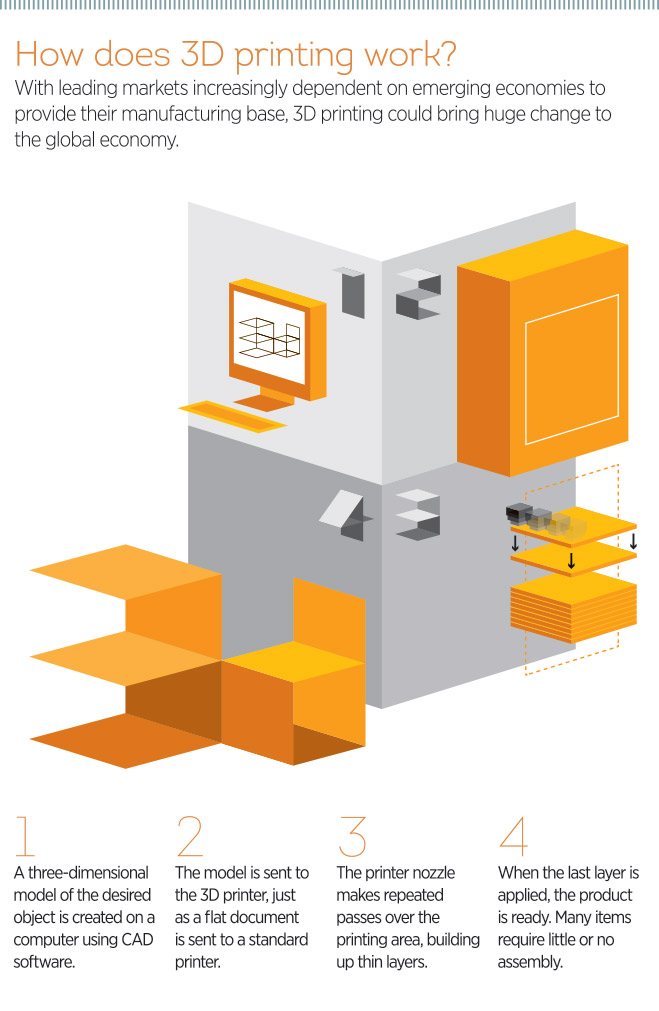

The concept behind 3D printing, the much-discussed new technology said to be on the verge of revolutionising industry, is often thought of as confusing, with some struggling to detach the thought of a traditional paper printer producing advanced physical objects. Also known as ‘additive manufacturing’, the process is widely regarded as the future of the manufacturing industry and is expected to transform the way in which a whole range of products are created.

While many sceptics believe the process will negatively impact upon the job markets, the advantages for both consumers and businesses are obvious. Companies as diverse as shoemaker Converse and Italian coffee manufacturer Alessi have been using 3D printing technology for a number of years to bring down costs and increase production speeds.

According to Converse, who use Z Corporation’s printing technology, production is 30 times faster. They have also been able to cut back eight annual trips to Asia, costing $12,000 per person, for design meetings. The cost of equipment required for production has also been dramatically slashed, with Converse saving $200,000 from its previous costs. A 70 percent decrease in costs, from shipping components and materials from overseas, allows for a far more profitable and efficient business.

“3D printing is set to totally reverse many countries’ overreliance

on manufacturing”

A considerable advantage of the speed with which 3D printing creates products is the allowance for on-demand manufacturing, which will sharply reduce the costs associated with unwanted stock. This should work in favour of smaller firms that don’t have the infrastructure to store and bulk-buy components, and especially those with just an online presence.

While online firms will benefit, a trend has emerged of shops with 3D printing machines springing up, offering clients the ability to customise their products in-store. They can select the colours, materials and size of whatever they are looking to buy.

Another advantage is the ability to cut down on the materials required to manufacture products. Aircraft manufacturers can waste up to 90 percent of the materials they use in making their planes. 3D printing requires less energy than traditional manufacturing processes and cuts down on waste. While this greatly reduces costs, it is also better for the environment. The 3D printing machines come with the added bonus of being multi-purpose. They eliminate the need for specialised machines and create a far more sustainable process.

As the world moves towards a more technologically advanced society and the tech-savvy youth begin to dominate the jobs market, the opportunities for developing new products through 3D printing software will be vast, while the need for traditional manufacturing and factory-based work will be less prominent. While this may reduce the employment opportunities for many current workers who may not be able to retrain, those entering the jobs market will be suitably skilled in many of the design applications and concepts involved in 3D printing.

Economies over the past century have been underpinned by their manufacturing industries due to the employment and output figures they produce. 3D printing is set to totally reverse many countries’ overreliance on manufacturing, creating more streamlined, efficient, greener and personalised industries.

Against 3D printing

Every few years, a new invention or technology comes along that has techies falling over themselves with excitement. In no time at all the media is up in arms, declaring a ‘new industrial revolution’ is imminent. The revolutionary technology du jour is the so-called 3D printer.

Of course, it’s not a printer at all. In fact, the technology produces a three dimensional object from a digital model by layering microscopic layers of plastic, resin or metal. The printer itself is essentially a gantry that allows a depositor to travel around 3D space, creating objects. In the future, as this technology is developed, it might well prove useful in some precision technology industries where the human hand is just not steady enough: but reports of its wider usefulness have been greatly exaggerated.

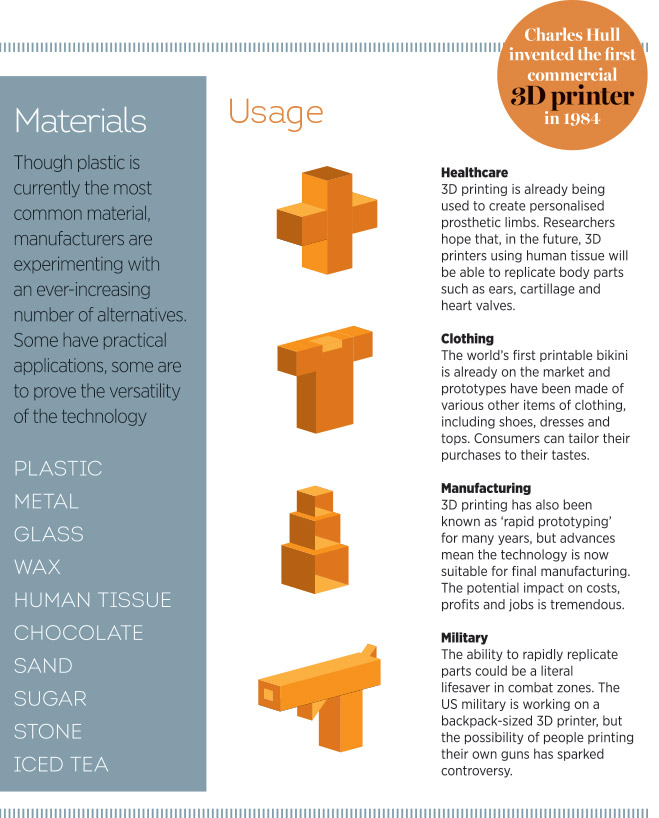

It has been suggested that these devices might soon be able to craft objects out of biological tissue, allowing doctors to produce cartilage, heart valves and other human bits-and-bobs. One group of scientists in the US is working on printing a human ear, but they estimate it will take around 20 years for the process to be perfected.

And that’s just the problem with 3D printing as we know it today: it is just not as diverse a technology as it has been made out to be. Most 3D printers use plastics, resins or powdered metals to produce the objects because they can only print things made of one particular material. Anything more complex than an intricate vase, a phone cover or a Star Wars action figure will have to be assembled using bits not made by the printer. Suddenly, it’s not looking so useful.

“The benefits of 3D printers do not outweigh the potential damage to the labour sector”

In fairness, these issues are likely to be overcome as the technology develops. By far the more important concern is the effect this cheap method of mass production will have on the labour market and manufacturing. When these machines are being touted as universal producers, the effects their widespread use could have on the manufacturing labour market are potentially catastrophic – and this at a time when many governments are already fighting to preserve their manufacturing industries.

3D printer-based production puts the designer in the centre of the manufacturing line and completely cuts out the manual labour element of the process. Billions of people work in factories and manufacturing jobs around the world, all of whom could potentially be left unemployed if cheap machines can print anything from guns to bras. Essentially, 3D printing can provide the skilled labour to produce complex designs, but without the need for a worker.

Furthermore, if the use of 3D printing becomes widespread, it would severely restrict the variety of skills required in the industry. All steps in the manufacturing process would be left in the hand of designers and perhaps engineers, further limiting the employment market. For the time being, the benefits of 3D printers do not outweigh the potential damage to the labour sector and, by extension, the political and economic spheres.

As the technology develops, 3D printing will be better suited to the precision industry than to widespread use in manufacturing. After all, consumers are already willing to pay a premium for ‘homemade’ or ‘handcrafted’ goods. No machine will be able to replace the superiority of a handcrafted object because human skill and creativity will always be the most valuable commodity.