PCO’s sCMOS camera systems give science new focus

With impressive image clarity and precision, PCO’s sCMOS image sensors are aiding scientific advancement and fast gaining attention among photography enthusiasts

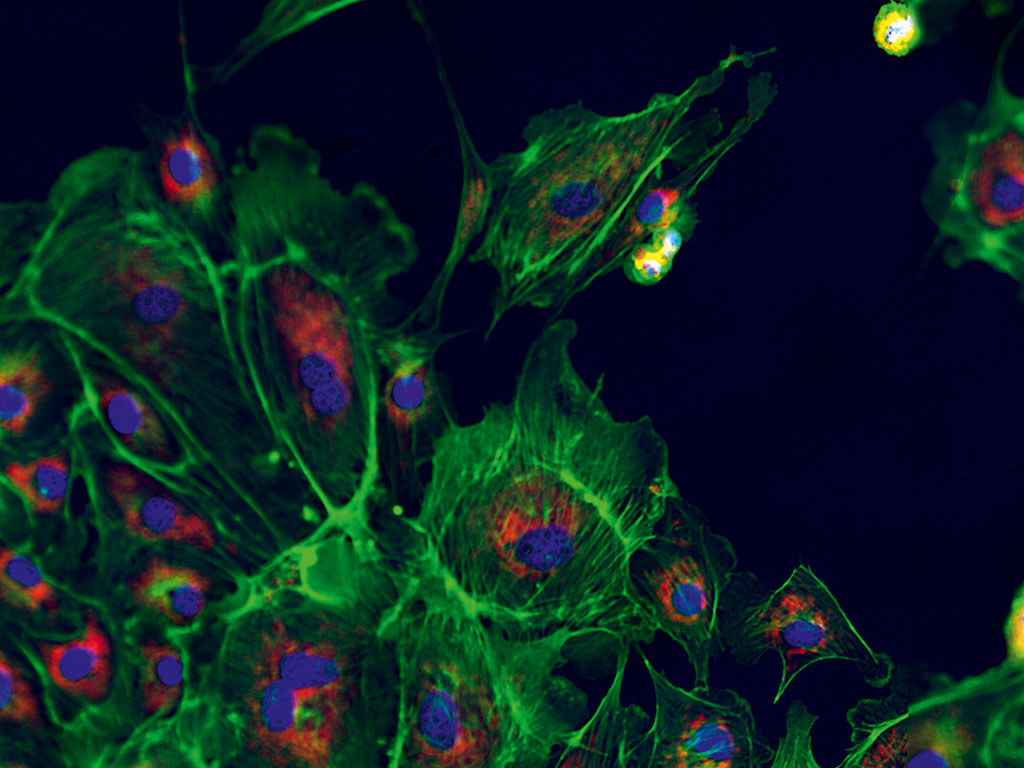

Part of a whole slide scan by a Pannoramic 250 Flash II slide scanner with a pco.edge sCMOS camera. False colour rendering, courtesy of 3D Histech. sCMOS cameras provide a high level of precision, making them an excellent tool for scientists and researchers

For more than 25 years, PCO has developed and manufactured high-performance CCD, CMOS and scientific CMOS (sCMOS) camera systems in the centre of Bavaria. Thanks to the quality and performance of our regional suppliers, we have been able to create camera systems for scientific imaging, quality control, and TV and broadcasting – as well as customers who just want a high standard of image quality.

In the past decade, this has led to us becoming engaged in the development of new images sensors. Such special requirements as high frame rates, high dynamics, high sensitivity and extremely low noise are not usually fulfilled by image sensors for consumer cameras.

For example, PCO joined with a group of companies to develop sCMOS sensors, and, based on customer feedback, initiated development of other CMOS image sensors.

Scientific CMOS

Let’s take sCMOS technology as an example. We created a family of sCMOS cameras including pco.edge 5.5, pco.edge 4.2, pco.edge gold 5.5 and pco.edge gold 4.2, which, together with other sCMOS cameras, became a breeding ground for new microscopy techniques.

Some of these new methods overcame the limits of the laws of diffraction and allowed life scientists to investigate in more detail the relationships in embryogenesis, interactions in cells, and other phenomena. Techniques such as superresolution or localisation microscopy, selective plane illumination microscopy, and structured illumination have let us increase the spatial resolution of light microscopy down to a couple of 10 nanometers.

In localisation microscopy, for example, the relevant parts of a cell, protein or whatever are marked with luminescent markers so that, if they are excited by appropriate light, only a few of them emit light at the same time. The distribution of single light emitting molecules is imaged by a light microscope. Due to the limit of diffraction and the small size of the molecules, only blurred spots in the image can be detected. If these spots don’t overlap, it can be assumed a single molecule is the origin, and the centre of mass of the spot can be evaluated. Then a map with the exact positions of the centres of mass of all the spots is stored and the next image taken, in which different molecules will be emitting light.

A larger sequence of images is subsequently recorded and processed in the same way, and a combined map in which all localisations are accumulated is generated. This creates an image with a much higher resolution than the optics of the microscope allow for.

Obviously, in this type of application high sensitivity, low noise and a high frame rate are required. The sCMOS camera allows all of these. Images can be recorded at a frame rate 10 times higher and with a higher degree of detection precision than the emCCD camera systems previously used. Now the images are ready in 10-20 seconds; before, it took minutes. This improvement allows more efficient research and a greater number of investigations to be conducted at once.

Applications in 3D

Even in the other areas in which they are used, PCO sCMOS cameras reduce the recording time of images and allow the investigation of dynamics on this spatial scale. In industrial applications – such as precise, high-contrast, 3D measurements of objects – the high intra-scene dynamic of sCMOS cameras is exploited. The large dynamic of the sCMOS technology allows the detection of the bright and very dark parts of the same scene.

Now the images are ready in 10-20 seconds; before, it took minutes

Since the raw data has a high 16-bit dynamic and therefore a high image content, it is up to the user how the raw data is displayed in the 18-bit world of screens and magazines. The image can be converted into a printable 8-bit format while retaining a large amount of data, The use of this high intra-scene dynamic can be extended to other applications, such as 3D measurements of so-called ‘non-cooperative surfaces’ (e.g. strongly reflecting metal parts in car manufacturing) and the 3D modelling of ancient buildings for disaster recovery. In all these applications, a large contrast within the same image has to be detected and processed.

While the sCMOS cameras allow the development of cutting edge techniques, they also allow existing applications to be taken to the next level. In areas such as digital pathology and confocal microscopy, imaging times are significantly reduced and image quality is improved.

In general

PCO keeps an eye on developments in CMOS image sensor technology and we work with research applications to create further developments. This, in conjunction with our excellent contact with customers, enables us to push the limits of camera technology. Healthy and steady growth, an expanding worldwide sales network (a sales office was opened in Singapore in 2013 for a better Asian service) are the driving forces for the future of the company.

But the fundament of the excellent situation at PCO is the motivation and creativity of PCO’s personnel, as proven by a low staff turnover. The plan for the future is to continue the advancement of camera technology for the benefit of our customers – and ultimately PCO.